CNC machining high precision hole skillsIn order to achieve high-speed and high-precision boring processing, it is necessary to pay attention to the influence of tool tooth vibration on surface rough

Read More..

How to prevent the deformation of sleeve-shaped parts during CNC machining cnc lathe machining separates roughing and finishing to reduce the influence of cutting force and cutting heat, so cnc lathe

Read More..

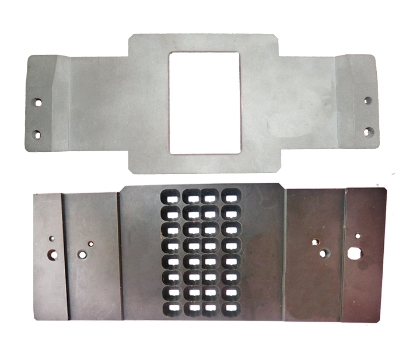

CNC precision machining welding wire pressure plateWire bonding is a very important part in the semiconductor packaging process. In the packaging and manufacturing process of components, in order to m

Read More..

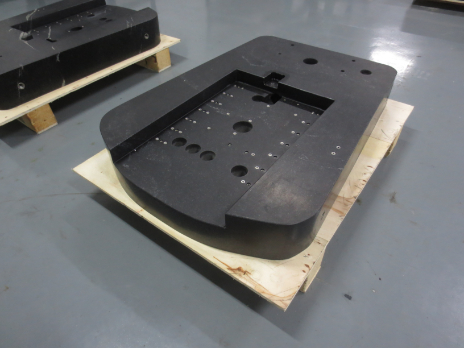

Five-axis precision parts processing in the shipbuilding industryThe fastest way to source low-volume, high-accuracy and complex parts in a variety of materials is by milling from solids, especially f

Read More..

CNC machining of medical precision partsMedical parts processingMedical parts precision machining (material, surface treatment) technologyCNC machining materials: metal (aluminum, steel, stainless ste

Read More..

improve the finish of CNC machining of auto partsNowadays, large-scale CNC machining has become an indispensable processing method in the processing of auto parts. When processing large auto parts, va

Read More..

Precautions for turning copper screws in CNC precision machiningWhen turning copper screws, first ensure that the copper content of the workpiece is at least 99.5% and above, and the hardness of pure

Read More..

Several Key Points to Improve the Quality of CNC Machining PartsControl the machining quality of CNC precision parts - tool selectionReasonable use of CNC machining tools, the processing of steel kniv

Read More..

The difference between brass fasteners and non-standard fastenersNon-standard parts processingIn the manufacturing process of fasteners, the first is raw material forming, and the forming process is e

Read More..

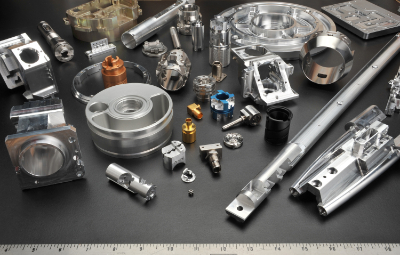

Guide to CNC Precision Machining of Semiconductor ComponentsCNC machining is one of those industrial technologies that evolves with the industry and effectively adapts to technological progress. This

Read More..