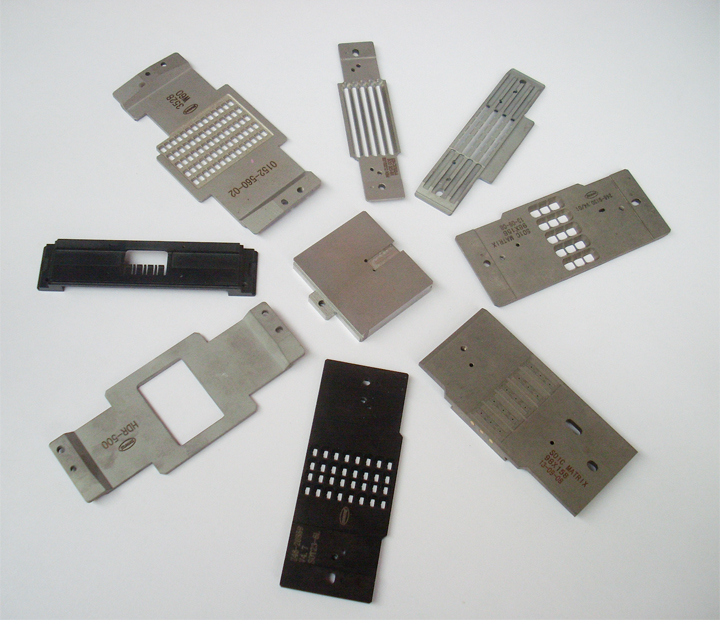

CNC precision machining welding wire pressure plate

Wire bonding is a very important part in the semiconductor packaging process. In the packaging and manufacturing process of components, in order to make the chip stick to the packaging carrier (such as lead frame or substrate, etc.), the bonding jig is also called wire bonding jig. Pressing plate, wire bonding machine hot pressing plate, quick pressing plate and wire bonding fixture are usually divided into upper cover plate (pressing plate) and heating bottom plate. They are mainly used for the electrical connection and wire bonding process of the carrier in the semiconductor packaging process, such as: LED Packaging, ic, etc., the welding jig can well fix the lead frame of the chip without shifting during the wire bonding process, avoiding the occurrence of problems such as missing soldering, crooked bonding wires, and virtual bonding wires, effectively improving semiconductor production efficiency

Wire bonding plate industry application

Soldering fixtures are commonly found in the electronics industry. It is widely used in various PCB welding (such as computer motherboards, graphics cards, ic, LED, etc.). As far as this industry is concerned, the main function is to position and fix the integrated circuit board, so as to realize the convenient welding of components and wiring on the integrated circuit board. Because it is an assembly line operation, it is required to be able to quickly achieve positioning and easy to take. Quick clamps are often used for compression. At the same time, due to the large number of components on the circuit board, components are not allowed to be pressed, so components are generally avoided, including positioning and pressing. in this way. Otherwise, it is easy to cause circuit malfunction. Or the product is scrapped. Of course, in some cases, the components to be welded are also fixed on the fixture, which requires the components and the circuit board to be fixed and the relative positions are correct. At the same time, there are certain requirements for the accuracy depending on the specific situation. It is more required that the PCB board should be placed flat, otherwise it is easy to cause problems such as poor welding components and warping. If it is working with automated equipment (such as automatic soldering machines), there are also considerable requirements for positioning accuracy. For example, the horizontal and vertical directions, and the vertical direction, all have accuracy requirements. In short, according to the requirements of PCB welding fixture, it is easy to operate, accurate in positioning, simple and practical.

Surface Treatment of Wire Clamps

The welding wire jig is generally made of high-quality cemented carbide material, and the surface is oxidized or hardened with black QPQ, which enhances the hardness of the fixture and is not easy to deform for a long time. It can effectively control the precision of the bonding wire, prolong the service life of the fixture, and save the fixture. cost. The jigs and fixtures produced by our company are light in design, reduce the load of the servo motor, and prolong the life of the wire bonding machine and die bonding machine. At the same time, we can design fixtures according to customer's process requirements. Applicable models: ASM, KS, KAIJO, Han's, Cui Tao, Youguang, Xinyichang, Weiheng and other wire bonding fixtures and fixtures.

/ServiceIndustry/semiconductor/

/ServiceIndustry/semiconductor/

Goodwill Precision Machinery has been deeply engaged in precision machining for 18 years, specializing in processing and customizing various high-precision parts for high-end customers at home and abroad, including various jigs and fixtures in the semiconductor packaging and testing industry. We have more than 300 European, American and Nissan products. Various high-end multi-axis CNC and other processing equipment can process ultra-precision parts with a maximum accuracy of ±0.001mm. With a group of design engineers and production technicians with many years of rich experience, we ensure that our products are at the forefront of the industry in both design and quality, and can better meet our customers and market needs.